Understanding the Pump Curve: Your Guide to Centrifugal Pump Performance

5th May 2021

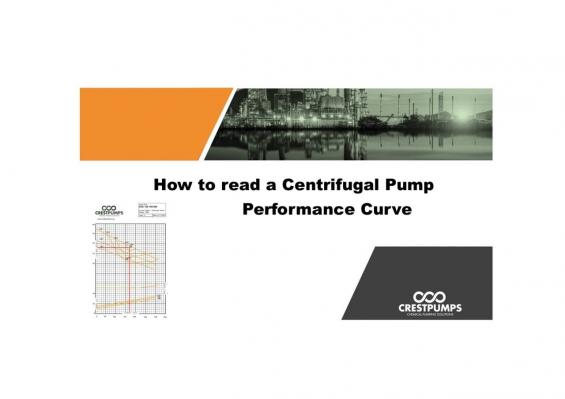

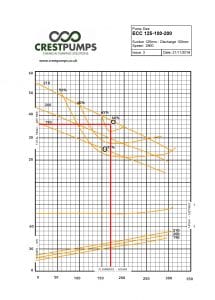

This may seem a basic topic but if new to selecting centrifugal pumps it is an essential skill to know. Pump manufacturers will supply a performance curve detailing the following information: flow, head, power absorbed, efficiency and NPSH required. On all curves some essential information will be shown such as the pump model, speed and suction and discharge sizes.

How to read a centrifugal pump performance curve

Duty Point: Let us assume a duty point required of 170m3/hr at a head of 36m. Shown as the red lines.

Flow can be read from the horizontal (X) axis.

Head is read from the vertical (Y) axis.

Impeller trim: In this case three impeller trims are shown; 210mm, 200mm and 190mm diameters.

Efficiency: We can see that the duty point sits very nicely at the BEP (Best Efficiency Point). Unless there are exceptional circumstances the pump should be at a point between 70% and 120% of its BEP.

NPSHr (Nett Positive Suction Head required): Reading down the vertical line we can see that the pump at this point requires an NPSH of 3m. Generally speaking NPSHr curves do not vary much between impeller trims. This is why we see only one NPSHr curve although three sizes of impellers are on the curve.

Power Required: Reading further down the vertical axis we can read the pump requires a power of 37.5 kw at the duty point (210mm impeller). The motor should take into account potential variations in the duty point so it is common practise to select the motor power for end of curve conditions.

Shut Off Head: The performance curve will also show the maximum head the pump can achieve at closed valve conditions. In this example we can read that the shut off head for a 210mm impeller is 55 metres.

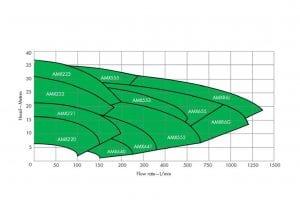

Tombstone or Composite Curves:

A guide produced to see the performance of a complete range of pumps. They are very similar in their format and used only to see which particular pump will suit the duty required and specific details can only be found on the individual pump performance curve.

We hope this article has helped you how to read a centrifugal pump performance curve, we also published a post recently learning about a system curve which you can find here.

We often post articles and other news on our LinkedIn page so please go and follow to keep up to date or for any pump queries you may have please contact us.