AIR OPERATED DIAPHRAGM PUMPS

Crest Debem AODD pumps offer exceptional reliability, versatility, and ease of use, making them the perfect solution for a wide range of industries and applications. Designed to handle viscous, abrasive, and corrosive fluids, they are ideal for chemical processing and transfer, water treatment, paper and pulp, as well as food and pharmaceutical industries.

Explore Our AODD Pump Range Here

Our range of air operated double diaphragm pumps include metallic, plastic, FDA and pharma approved materials and can be supplied certified to ATEX zone 1 or 2, from 1/2" to 3" and suitable for all applications from small machine mounted applications to larger requirements. We hold a large stock of plastic pumps and metallic air operated diaphragm pumps, and non standard AODD pumps are available on short lead times.

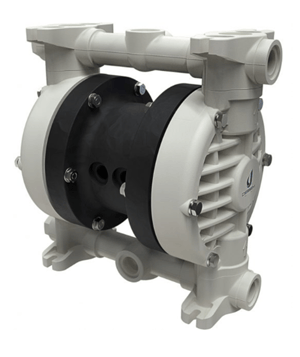

AODD pumps in metallic or plastic material. Ideal for pumping liquids with high apparent viscosity even if containing suspended solids. The vast range of materials available makes them compatible with any type of fluid present on the market.

View BOXER

FDA compliant AODD pumps for the food industry. These pumps are ATEX-IECx certified and built in AIS316/AIS316L. Suitable for handling fluids with high apparent viscosity and demanding applications.

View FOODBOXER

A real must for any pneumatic pump in those applications where a smooth regular fluid output is required. These are also available as ATEX-certified, making them suitable for potentially explosive environments.

View PULSATION DAMPENERS

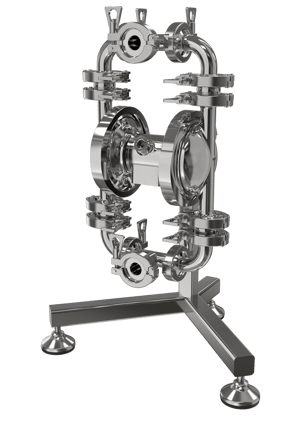

Volumetric diaphragm pumps driven by compressed air with double diaphragm built in. Mechanically polished AISI316L Aiserboxers are MOCA ATEX and FDA certified.

View AISIBOXERS

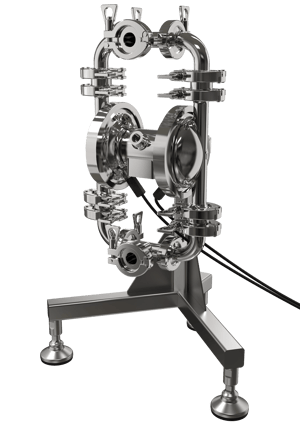

AODD pumps designed for use in pharmaceutical and cosmetic industries. Equipped with special fibre optic sensors to detect any damage to the diaphragms.

View SANIBOXER

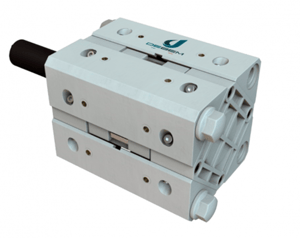

Double diaphragm pumps of the RC line have been designed for all applications that require the pump to be controlled remotely or directly by the machine on which the pump is installed.

View REMOTE CONTROL

The ATEX air operated double diaphragm pumps with their unique design and limited size are ideally suited in applications where moderate quantities of fluid must be pumped into small spaces.

View CUBIC

What You Get When You Choose Crest Pumps

Trusted By The Best