Metal Finishing Industry

Reliable, Corrosion-Resistant Pumps for the Metal Finishing Industry

Our Pump Solutions for the Metal Finishing Sector

Featuring a standard 400mm column length. The vertical Surge range is suitable for all types of applications including metal treatment, tank emptying transfer and re-circulation

View Range

Built with a cantilever shaft design, CSS Pumps have no immersed bearings which allows the pump to run drywithout damage. Available in polypropylene or PVDF

View Range

The EOV range of mechanically sealed pumps gives you up to 15% increase in performance whilst consuming up to 20% less power.

Read More

Plastic magnetic drive pumps ideal for processing clean, corrosive liquids. The centrifugal forces is driven by two rotating magnets eliminating the need for a mechanical seal, making the pump both seal-less and leak-proof.

View Range.png?width=300&name=PTCX5-removebg-preview%20(1).png)

316L Stainless Steel mag drive pumps with SiC internals. Suitable for both safe area and ATEX applications.

Read More

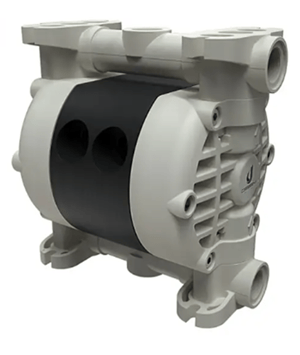

Debem air operated diaphragm pumps are a positive displacement pumps that use compressed air instead of an electric motor. Ideal for self-priming, solids handling or run dry applications.

Read More

Constructed from 316 stainless steel or cast iron, with multiple impeller and seal options, this range is suitable for a vast range of applications from simple water transfer to processes with high viscosities (<700Cp), solids or gas/air pumping (<15% air).

Read More

The PPS plastic vertical pump range is efficient, heavy duty and reliable at a competitive price. Not only is the PPS rigid and vibration free, but it's capable of being installed for many years of trouble free service in sump emptying applications with column lengths from 1 - 4.5m.

Read MoreMetal finishing is a challenging industry for any pumping solution. For processes like electroplating, anodising or chemical etching, being able to rely on pump performance and lifespan is crucial. One of the challenges our customers in the metal finishing industry face are unique and require specialised pumping solutions and expertise:

- Energy efficiency and cost-effectiveness: The running costs in metal finishing can be high, meaning a need for energy-efficient pumps that reduce waste and maximise productivity.

- Efficiency and reliability in process: Any failure of the pumping process will drive the creation of defective coatings or inconsistent finishes.

- Health, safety & environmental compliance: The handling of hazardous chemicals demands rigorous adherence to regulations and best practice to guarantee worker safety and environmental protection.

- Corrosion and degradation of mechanical components: Many metal finishing processes use very aggressive chemicals that require highly resistant materials in the constructions of pumps to prevent failures and downtime.

Crest Pumps has many years of experience in supplying corrosion-resistant pumps that can cope with the hazardous chemicals and extreme temperatures involved in metal finishing applications. Whether its electroplating, anodising or chemical etching, the quality of the final product is only as reliable as the pump behind the process.

- Energy efficiency & cost effectiveness: With long running hours and high chemical volumes, operations costs can be significant. Crest Pumps are engineered for high energy efficiency, helping to reduce waste, minimise energy consumption , and improve long-term cost performance without compromising output.

- Process reliability & consistent performance: Crest Pumps are built for continuous operation, delivering stable flow rates and chemical compatibility to ensure high quality finished across every batch.

- Health, safety & environmental compliance: Crest's seal-less and leak-free pump designs help meet strict health and environmental standards, protecting both personnel and the surrounding environment from hazardous exposure.

- Corrosion resistance & longevity: Our pumps are constructed from advanced corrosion-resistant materials, ensuring long service life, reduced downtime and fewer replacements - even in the harshest chemical environments.

Where can I use Crest Pumps?

Real Life Solutions for Real Life Challenges

Crest Pumps has a long-standing reputation for supplying high-quality pumps to the metal finishing sector.

Bowmill Metal Treatment

Implemented CSS Range pumps to handle aggressive solutions, reducing downtime and maintenance costs.

Twickenham Plating Group

Upgraded their pumping system to a Crest Pumps solution, improving efficiency and reliability in their electroplating process.

Crest Pumps provides a range of corrosion-proof chemical pumps for metal finishing applications. Our CSS Range of Magnetically Driven Chemical Process Pumps is the perfect choice for the more aggressive chemicals, providing a maintenance-free, leak-free service.

Cut Costs and Maximise Efficiency.

Our pumps keep your operation flowingCertifications and Compliance

Crest Pumps is dedicated to producing the highest-quality, most reliable pumps for metal finishing. Our products are manufactured to represent the highest standards of performance.

-

ISO 9001:2015: The quality management system is certified, assuring the consistency and reliability of products.

-

Explosive Tending Environments: Explosion-proof pumps for hazardous environments are available under ATEX certification.

-

WRAS Approved Materials: They fully comply with safety and material regulations.

Why Crest Pumps for the Metal Finishing Industry?

Many metal finishing processes employ highly aggressive chemicals, necessitating pump construction from resistant materials to avert failures and costly down-time.

Any disruption to the pumping process may lead to defective coatings or inconsistent finishes that can affect product quality.

The operating cost for metal finishing could be tremendous, making it imperative to use energy-efficient pumps to minimise wastage and optimise productivity.

Trusted By The Best