Oil & Gas Industry

Reliable, Corrosion-Resistant Pumps for the Oil and Gas Sector

Our Pump Solutions for the Oil & Gas Sector

.png?width=300&name=RD-RG-RC-RB%20(2).png)

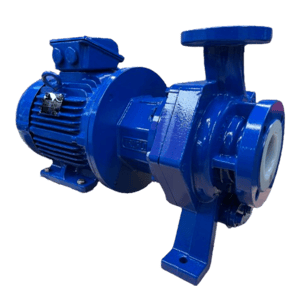

The RD-RG-RC-RB range of heavy duty end suction process pumps are designed for all applications from water to corrosive or solvents including ATEX Zone 1 and 2. Built to ISO2858 and En25199 and come with a choice of impeller designs to best fit your application

View Range

Extremely efficient when pumping harsh and corrosive chemicals that include solids 60% of the size of the discharge port. An ideal solution when emptying wastewater sumps.

View Range

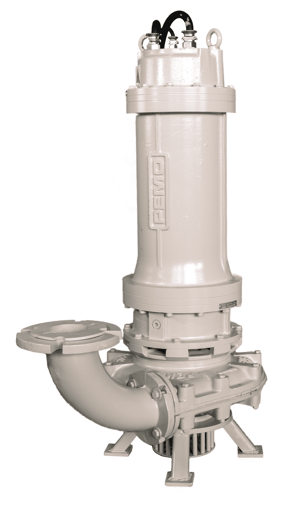

Pemo submersible, vertical and end suction pumps for slurry & abrasive fluid applications in rubber lined and hard alloy construction. Also available in other materials.

View Range

USA made Truflo ANSI mag drive pump range conforming to ANSI spec with quick deliveries. Sealless operation & all wetted parts are made from ETFE fluoropolymers.

Read More

ASSOMA plastic mag drive pumps, as a seal-less pump they eliminate the risk of leakage which prevents unplanned downtime as well as damage to the environment and expensive clean-up bills. Ex-stock availability.

Read More.png?width=300&name=PTCX5-removebg-preview%20(1).png)

PTCXPUMP magnetic drive pumps constructed from 316L Stainless Steel with SiC internals.

Read More-(modified)_Page_1_Image_0010.jpg?width=300&name=TRUFLO---Line-Card-(HiRes)-(modified)_Page_1_Image_0010.jpg)

USA made Truflo complete line of API 610 pumps designed to handle a wide variety of chemicals, process liquids & petroleum products.

Read More

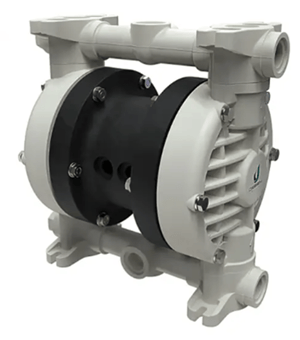

Air operated diaphragm pumps are positive displacement pumps that use compressed air instead of an electric motor. Ideals for sekf-priming, solids handling or run dry applications.

Read MoreWithin the oil and gas sector, high-risk application environments can place pumping equipment in some of the harshest operating conditions. Aggressive chemicals, high temperatures and hazardous fluids require highly reliable pumps that can withstand corrosion and comply with extremely stringent safety and environmental regulations. Some of the challenges include:

- Environmental and safety regulations: Industry regulations insist on leak and spill-proof measures to ensure that there is no contamination.

- Continuous operation and low maintenance: Any downtime spells loss of production.

- Corrosion and chemical resistance: Corrosive chemicals, hydrocarbons and saltwater require environmentally resistant pumps.

- High temperatures and pressure: Pumps must endure very high temperatures and carry out different processes at elevated pressures.

- Explosion-proof and ATEX-compliance: Our equipment has been designed and built to meet the very highest standards of safety, particularly for high risk areas.

Crest Pumps has been supplying chemical- and corrosion-resistant pumps for the oil and gas industry for decades. From offshore platforms to refinery processes, Crest Pumps supplies pumps which provide high performance, durability and efficacy, assuring the continuity of its operations and compliance with regulations.

- Reliable containment for hazardous fluids: Crest's fully sealed, leak-free designs ensure full containment of volatile fluids and help maintain safety and environmental compliance.

- Built for continuous operation: Downtime costs money - and trust! Our pumps are engineered for long-term, maintenance-light performance, delivering reliable operation, even in remote or hand-to-access locations.

- Resilience in corrosive environments: From saltwater exposure to aggressive hydrocarbons, Crest Pumps are built using chemically resistant materials that hold up against even the most damaging process conditions.

- Engineered for extreme conditions: Our pumps can withstand intense heat, pressure and mechanical stress, making them ideal for use across all phases of oil and gas production including refining, transport and extraction.

Where can I use Crest Pumps?

Real Life Solutions for Real Life Challenges

Our PPM Mech Seal Range is designed for high-efficiency pumping of corrosive and hazardous chemicals, with robust mechanical seals for leak-free operation.

ConocoPhillips PPM Mech Seal Range

ConocoPhillips submitted their enquiry to Crest Pumps for a process pump that would be built to the exacting rig requirements, including a seal flush plan, long coupled and with a bronze coupling guard. Crest Pumps Group supplied the PPM32/3 mechanical seal pump.

CSS Range Self-Priming Magnetic Drive Pumps

Vallourec is the world leader in premium tubular solutions predominantly for the Oil and Gas industry. At the Bellshill plant near Glasgow, phosphoric acid is used to coat the flange ends and prevent them from corrosion and rust. The CSS Range is an ideal pump for the job.

Looking for a reliable pump solution for your oil and gas operation?

Contact Us TodayCertifications and Compliance

Crest Pumps’ wealth of knowledge and experience in the oil and gas industry is evident thanks to gaining all necessary certification and compliance. This guarantees safety, consistency and regulatory compliance.

-

ATEX-certified Pumps: Explosion-proof pumps for hazardous environments.

-

ISO 9001:2015 : Quality management certification guaranteeing uniform and reliable performance.

-

API 610 and API 685 Compliance: Regarding pump reliability and safe operation in hydrocarbon processing.

Why Crest Pumps for the Oil & Gas Industry?

Expertise in delivering customised pump solutions for oil and gas applications.

Designs that meet the precise requirements of your operation.

For long life and reliable performance even in the most extreme conditions.

Helping businesses save both money and the environment.

Trusted By The Best