Energy Production Industry

Specialist Pumping Solutions for the Energy Sector

Crest Pumps delivers proven, high efficiency pumping solutions for the energy production industry. From waste-to-energy to biomass power plants, our pumps offer seamless, efficient operation for safety, compliance and sustainability.

Our Pump Solutions for the Energy Sector

The AVF-C plastic canned motor mag drive pump is built to save you energy - with the highest motor efficiency (IE5 & GB1 equivalent), highest pump efficiency (Minimum Efficiency Index, MEI >0.7), and variable frequency drive meaning the smallest carbon emissions chemical pump you can buy.

View Range

PTCXPUMP magnetic drive pumps constructed from 316L Stainless Steel with SiC internals, ideal for chemical, electronics, carbon capture & semi-conductor applications.

View Range

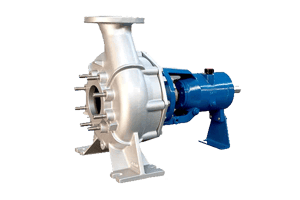

The RD-RG-RC-RB range of heavy duty end suction process pumps are designed for all applications from water to corrosive or solvents including ATEX Zone 1 and 2. Built to ISO2858 and En25199 and come with a choice of impeller designs to best fit your application

View Range

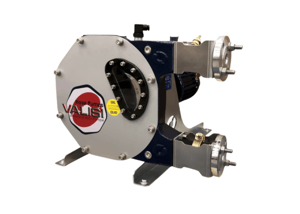

VALISI peristaltic hose pumps are ideal for transfering and dosing a wide range of fluids in different applications. They are sealless, as the hose contains the pumped liquid thus eliminating the possibility of fluid contamination.

Read More

The HD-DG-RS range of horizontal, centrifugal mechanically sealed pumps are constructed from 316 stainless steel or cast iron, with multiple impeller and seal options, this range is suitable for a vast range of applications from simple water transfer to processes with high viscosities (<700Cp), solids or gas/air pumping (<15% air).

Read More

Pemo slurry pumps are available in Vertical, Horizontal, Submersible and Multi-Stage versions. Capacities range from 1 to 2000 m3/h, head for single-stage pumps can reach 90 m (295 ft)

Read MoreOvercoming Energy Production Industry challenges with Crest Pumps

Crest Pumps delivers proven, high efficiency pumping solutions for the energy production industry. From waste-to-energy to biomass power plants, our pumps offer seamless, efficient operation for safety, compliance and sustainability.

Some of the main challenges our customers face in the energy production sector are unique and require specialised pumping solutions, such as:

- Regulatory Compliance: Equipment used within hazardous zones requires ATEX certification for safe operation.

- Corrosion Resistance: Aggressive and high temperature fluids demand strong, corrosion resistant materials to handle the toughest of production schedules.

- Shell Efficiency: Energy conservation and operational cost cutting are key in sustainable power generation.

- Harsh Environments: Pumps need to be built to withstand extreme temperature and hydraulic pressures as well as exposure to corrosive substances.

From Biomass to waste-to-energy, the energy production sector demands equipment that can withstand tough conditions, maintain high performance, and meet strict regulatory standards. Crest Pumps offer proven solutions that deliver on all fronts, from compliance to efficiency.

- ATEX certified for hazardous zones: We offer a full range of ATEX certified pumps designed for explosive and hazardous environments, ensuring complete compliance with safety regulations in power generation facilities.

- Built for corrosive and high temperature fluids: Energy production often involves aggressive chemicals and extreme temperatures. Crest Pumps are constructed from corrosion-resistant materials such as PVDF, Polypropylene and Stainless Steel, offering robust performance even under the most demanding conditions.

- Maximising energy efficiency: Our high efficiency pump designs significantly reduce energy consumption and operational costs, making them ideal for modern power plants focused on performance and sustainability.

- Engineered for harsh environments: Whether dealing with thermal stress, abrasive sludges, or high pressure flows, Crest Pumps are designed to withstand extreme operating environments - providing long term reliability and minimal downtime.

Where can I use Crest Pumps?

Real Life Solutions for Real Life Challenges

Crest Pumps offers a wide selection of pumps for supporting critical energy processes with durability and performance for efficiency.

Self-Priming: RD-RG-RC-RB Range – ENGIE Fabricom

Eight RD-RG-RC-RB pumps were supplied by Crest Pumps, for installation in ENGIE Fabricom's waste-to-energy facility, processing of 250,000 tonnes of household waste. This pump works effectively against effluent water rates below 300 m3/hr to enable a smooth operation of the water-steam cycle.

High-Efficiency Stainless Steel Pumps: HD-HG-RS Range – Biffa

Crest Pumps supplied pumps from the HD-HG-RS range to Biffa's anaerobic digestion facility where fumes and gases neutralised throughout the energy generation process. - 316 stainless steel ensures safe circulation of ammonium liquor, improving safety and efficiency.

High performance, low maintenance, 100% reliable

Our pumps keep your operation flowingCertifications and Compliance

Crest Pumps comply with the highest industry standards, ensuring our pumps are compliant with the tough safety and performance obligations of the energy sector:

-

ATEX Certification for safe operation in explosive environments.

-

ISO 9001:2015 Quality Management for consistent manufacturing excellence.

-

Corrosion-Resistant Materials include stainless steel, polypropylene and PVDF assuring long-term durability.

- Leak-Free Magnetic Drive Technology guarantees environment protection and workplace safety.

Why Crest Pumps for the Energy Industry?

Crest Pumps have been supplying leading energy companies for decades.

Creating solutions with your plant's performance needs in mind.

Applying high-performance pumps engineered for cost savings.

Designed to resist and survive harsh environments and extreme operating conditions with minimal maintenance.

Trusted By The Best