Food & Beverage Industry

Reliable Pumping Solutions for the Food and Beverage Industry by Crest Pumps

Crest Pumps specialises in providing robust, efficient, hygienic and safe pumping solutions specifically designed for the food and beverage sector. We have decades of experience with food-safe fluids as well as corrosive substances. All our pumps are engineered to meet rigorous industry standards while ensuring exceptional efficiency and reliability.

Our Pump Solutions for the Food & Beverage Sector

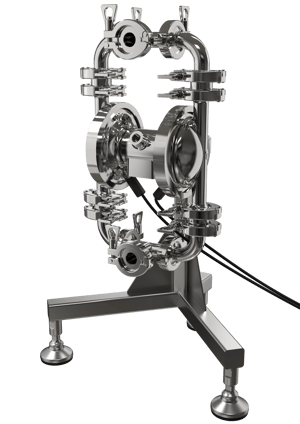

Magnetically driven pumps are driven by two rotating magnets rather than being directly coupled to a motor. This eliminates the need for a mechanical seal and therefore making magnetic drive pumps sealless and leak proof.

View Range

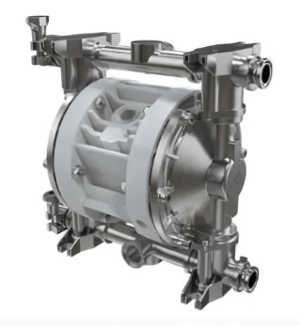

The pumps of the SANIBOXER line are equipped with special fiber optic sensors to detect any damage to the diaphragms, resulting in fluid leaks. In the event of a malfunction, the sensors warn the operator and automatically stop the pump's work.

Read More

The Surge range replaces the previous VSL range but with developments in the casing and impeller design, generating up to 30% greater performance whilst consuming less power. All Surge pumps feature a standard column length of 400mm.

Read More

FDA compliant pumps for the food industry. These pumps are ATEX-IECx certified and built in AIS316/AIS316L. Suitable for handling fluids with high apparent viscosity and demanding applications.

View Range

316L Stainless Steel mag drive pumps with SiC internals. Suitable for both safe area and ATEX applications.

Read More

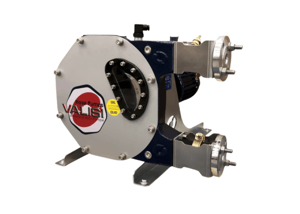

VALISI peristaltic hose pumps are ideal for transfering and dosing a wide range of fluids in different applications. They are sealless, as the hose contains the pumped liquid thus eliminating the possibility of fluid contamination.

Read More

The Vertical range of stainless steel pumps is engineered for maximum efficiency when handling harsh, corrosive chemicals and solids up to 60% of the discharge port size—making them an excellent solution for wastewater sump emptying and other demanding applications.

Read MoreOvercoming Food & Beverage Industry challenges with Crest Pumps

Crest Pumps specialises in providing robust, efficient, hygienic and safe pumping solutions specifically designed for the food and beverage sector. Some of the main challenges our customers face in the food and beverage industry are unique and require specialised pumping solutions, such as:

- Compliance: All our pumps conform to the stringent standards and regulations set out by organisations such as the FDA & ATEX regarding both food safety standards and hazardous environments.

- Hygiene Standards: Ensuring compliance with stringent hygiene protocols is vital to prevent contamination and guarantee food safety.

- Energy Efficiency: Today more than ever, it's essential to minimise operational costs while maximising performance for sustainable practices. Green is good!

- Resistance to Corrosion: Many processes involve acidic or alkaline substances that require pumps constructed from non-corrosive materials.

- Adaptability: Pumps need the ability to manage fluids of various viscosities at different temperatures.

From clean-in-place systems to handling aggressive cleaning chemicals, the food and beverage sector demands hygienic, reliable, and efficient pumping systems. With decades of experience, Crest Pumps provides tailored solutions that prioritise food safety, compliance, and long term performance.

- Full regulatory compliance: Our pumps are engineered to meet FDA & ATEX standards, ensuring full compliance with food-grade safety regulations and operation in hazardous environments where required.

- Designed for strict hygiene standards: Crest pumps feature smooth internal surfaces and easy-clean materials to help prevent contaminations and meet the hygiene demands of food production environments.

- Energy-efficient operation: We design our pumps to deliver maximum performance with minimal energy use, helping reduce operational costs while supporting more sustainable, energy-conscious manufacturing.

- Built to resist corrosion: Whether handling acidic flavourings, cleaning chemicals, or saline solutions, our pumps are built from non-corrosive materials like PVDF and Polypropylene to ensure lasting reliability.

- Adaptable to varying fluid types: From light beverages to viscous sauces or syrups, we offer flexible performance across a wide range of viscosities and temperatures, ensuring consistent flow and precision.

Where can I use Crest Pumps?

Real Life Solutions for Real Life Challenges

Crest Pumps provides a diverse selection of hygienic and durable pumps designed especially for processing within the food sector

AM Pump Series – Magnetic Drive Technology

The traditional British brewery Bowman Ales required an efficient pump minimising contamination risk during ingredient transfer.

Our AM Pump presented a leak-free design devoid of seals, which ensures their brewing process's integrity while vastly reducing maintenance requirements.

Food and Drink? Safety First!

Talk to the Experts

Certifications and Compliance

Crest Pumps maintains strict compliance to leading industry certifications verifying our commitment towards quality assurance in product output:

-

Using only materials compliant with FDA guidelines guarantees safe fluid handling suitable for consumption-grade applications.

-

Possession of ATEX certification allowing operation in areas susceptible to explosions during production processes integrates additional layers of security.

-

Certification under ISO 9001:2015 assures ongoing consistency in product reliability through comprehensive quality management systems.

Why Crest Pumps for the Food and Beverage Industry?

Maintaining Hygiene and content integrity throughout the pumping process.

Crest Pumps achieve the highest performance levels in the market. Lower running costs and minimal maintenance.

The best materials for the job: corrosion-resistant materials like PVDF and polypropylene. Hygienic, safe and cost effective.

The Food and Beverage sector needs pumps that can handle high and low viscosity flow rates.

Trusted By The Best