AVF-X Range

Ultra Efficient Magnetic Drive Plastic Pump

Runs cheaper, lasts longer, and saves you more.

The AVF-X series is one of the first plastic magnetic drive pumps to meet the highest European pump efficiency standards on the market (Commission Regulation (EU) No. 547/2012 with an MEI ≥0.7). This means you can rest assured knowing you are using one of the most energy efficient pumps available and benefiting from exceptional energy savings in your production processes whilst reducing your overall carbon footprint.

Stop replacing pumps and start investing in performance.

Chemical Resitant Pumps The AVF-X series is one of the first plastic magnetic drive pumps to meet the highest European pump efficiency standards on the market (Commission Regulation (EU) No. 547/2012 with an MEI ≥0.7). This means you can rest assured knowing you are using one of the most energy efficient pumps available and benefiting from exceptional energy savings in your production processes whilst reducing your overall carbon footprint.

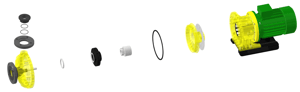

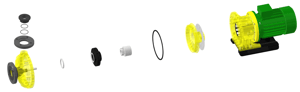

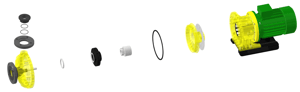

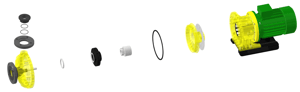

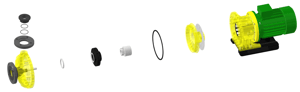

The AVF-X Series features breakthrough designs focused on improving pump efficiency. Superseding the AMX range, the volute and impeller have been completely re-designed with a 3-Dimensional impeller and centreline volute casing to enable even longer service life whilst consuming less energy and reducing your running costs. With pumps accounting for half of all the energy consumed in an industrial plant, we believe that every pump should be reliable and efficient because if your pump doesn’t perform well, your plant won’t either.

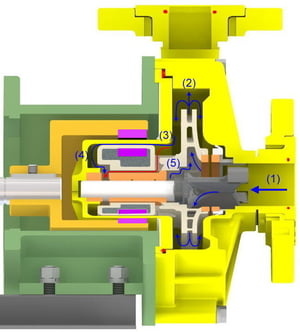

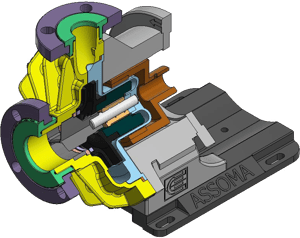

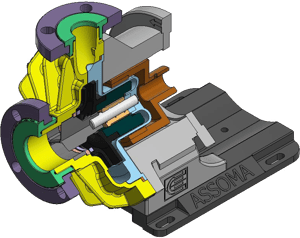

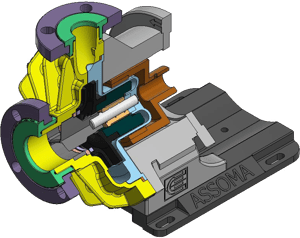

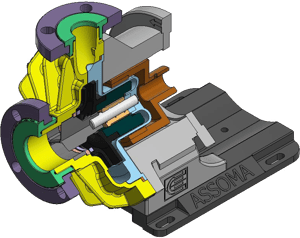

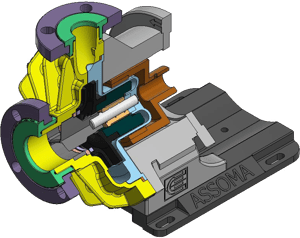

The AVF-X Series of pumps handle highly corrosive or toxic chemicals for everyday applications. The sealless, magnetic-drive construction fully contains the chemical to prevent leakage and pollution of your work environment. Mag drive pumps work by using a magnetic coupling to transfer the mechanical energy from the motor to the pump's impeller. A drive magnet is attached to the motor shaft and on the pump side, an inner magnet is attached to the pump impeller. The magnetic flux between the drive and inner magnets pass through the pump containment shell, forming the magnetic coupling and allows the pump to be hermetically sealed for leak-free operation.

Contact us to learn more about how our AVF-X series pumps can help you achieve your climate goals. If you need a variable speed pump with the same high -efficiency pump design, check out our AVF-C pumps for even greater energy savings!

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Patented Run Dry Design

Under normal conditions, pumped liquid cools and lubricates the pump. But when starved of liquid, heat from friction can cause damage.

Crest Assoma’s Mag Drive range prevents this with a patented auxiliary circulation channel, cooling the bearing without reducing pump efficiency—even in dry-run scenarios.

For a smarter, more cost-effective solution, use our Life Cycle Cost (LCC) analysis to compare pump options and find the most efficient choice.

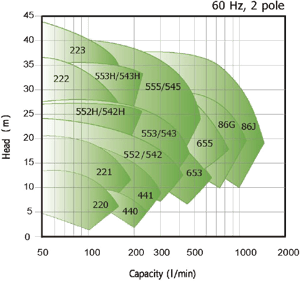

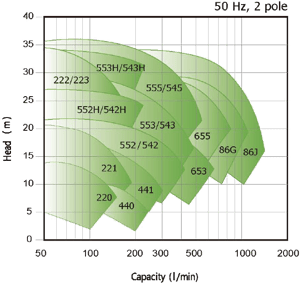

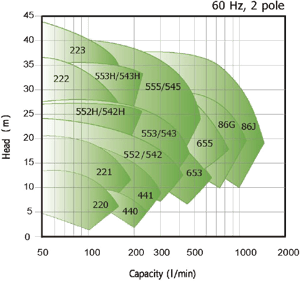

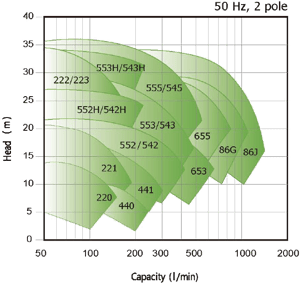

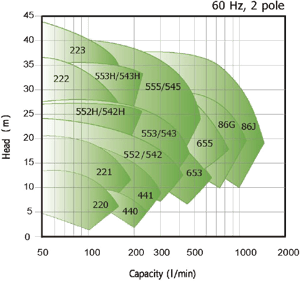

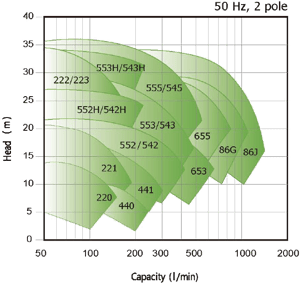

Technical Specification

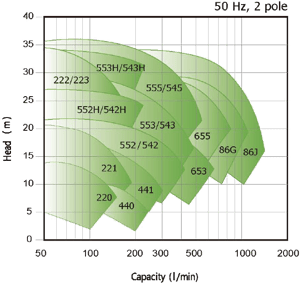

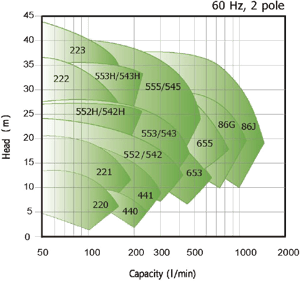

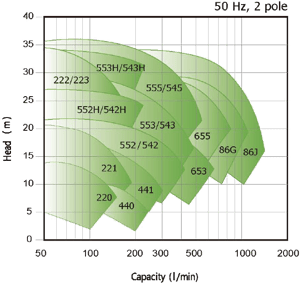

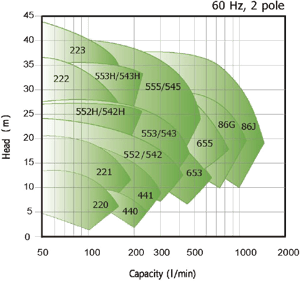

| Model | Suction (mm) | Discharge (mm) | Speed (rpm) | Rated Capacity (L/min) | Rated Heat (m) | Motor Output (kW) |

| AVF-X 220 | 25 | 25 | 2900 | 100 | 12.4 | 0.37 |

| AVF-X 221 | 25 | 25 | 2900 | 120 | 18 | 0.75 |

| AVF-X 222 | 25 | 25 | 2900 | 80 | 33.2 | 1.5 |

| AVF-X 223 | 25 | 25 | 2900 | 80 | 33.2 | 2.2 |

| AVF-X 440 | 40 | 40 | 2900 | 120 | 10 | 0.37 |

| AVF-X 441 | 40 | 40 | 2900 | 200 | 14 | 0.75 |

| AVF-X 552 | 50 | 50 | 2900 | 200 | 20 | 1.5 |

| AVF-X 552H | 50 | 50 | 2900 | 150 | 26.1 | 1.5 |

| AVF-X 553 | 50 | 50 | 2900 | 250 | 25.6 | 2.2 |

| AVF-X 553H | 50 | 50 | 2900 | 150 | 33 | 2.2 |

| AVF-X 555 | 50 | 50 | 2900 | 300 | 32 | 3.75 |

| AVF-X 653 | 65 | 50 | 2900 | 540 | 15.5 | 2.2 |

| AVF-X 655 | 65 | 50 | 2900 | 600 | 25.9 | 3.75 |

| AVF-X 86G | 80 | 65 | 2900 | 1000 | 21.2 | 5.5 |

| AVF-X 86J | 80 | 65 | 2900 | 1000 | 26.3 | 7.5 |

Frequently Asked Questions

Magnetic drive pumps are used in a wide variety of applications, including chemical processing, water treatment, and metal finishing. They are designed to provide a reliable and efficient solution for transferring corrosive and hazardous liquids. The pumps are constructed with a non-metallic construction, making them ideal for use in highly corrosive and hazardous environments.

Magnetic drive pumps are centrifugal pumps that use a magnetic coupling to transmit power from the motor to the impeller. The drive magnet is mounted on the motor shaft that will connect by magnetic force to driven magnets contained within the pump. This type of pump is ideal for applications where leakage or contamination of the pumped fluid is a concern, as there is no mechanical seal or shaft seal to fail.

Pumps are an essential part of many industries, and it is important that they operate as efficiently as possible. The Minimum Efficiency Index (MEI) is a metric used to measure the efficiency of a pump. MEI is particularly important for pumps exceeding 0.7 because it can help users save money on energy costs and reduce their carbon footprint.

What is the Minimum Efficiency Index (MEI) for Pumps?

The Minimum Efficiency Index (MEI) is a measurement of the efficiency of a pump. MEI is calculated by dividing the actual pump efficiency by the minimum efficiency for that type of pump. The minimum efficiency for each type of pump is set by the standards organizations such as the Hydraulic Institute and the European Union. The higher the MEI, the more efficient the pump is.

Why is MEI important for pumps exceeding 0.7?

MEI is particularly important for pumps exceeding 0.7 because it can help users save money on energy costs and reduce their carbon footprint. Pumps that exceed 0.7 are typically larger and more powerful, and they use more energy than smaller pumps. Therefore, even a small increase in efficiency can result in significant energy savings. In addition, using a more efficient pump can help reduce greenhouse gas emissions, which is an important consideration for many industries.

What are the benefits of using a pump with a high MEI?

- Lower energy costs: Since a more efficient pump uses less energy, it can help users save money on energy costs.

- Reduced carbon footprint: Using a more efficient pump can help reduce greenhouse gas emissions, which is an important consideration for many industries.

- Improved reliability: A more efficient pump is likely to last longer and require less maintenance than a less efficient pump.

- Better performance: A more efficient pump is likely to perform better, which can help improve overall process efficiency.

How can Crest Pumps help with MEI for pumps?

At Crest Pumps, we specialize in the design and manufacture of high-efficiency chemical resistant pumps. We understand the importance of MEI for pumps exceeding 0.7, and we can help our customers select the most efficient pump for their application. We offer a range of pumps with high MEI values, and we can provide expert advice and support to help our customers reduce their energy costs and carbon footprint.

|

Benefits |

How Crest Pumps Can Help |

|

Lower energy costs |

We offer a range of pumps with high MEI values, which can help our customers save money on energy costs. |

|

Reduced carbon footprint |

We understand the importance of reducing greenhouse gas emissions, and we can help our customers select pumps with the highest MEI values to achieve this goal. |

|

Improved reliability |

Our pumps are designed for reliability and long life, which can help our customers reduce maintenance costs and downtime. |

|

Better performance |

We offer pumps with high MEI values, which can help our customers improve overall process efficiency and performance. |

Conclusion

The Minimum Efficiency Index (MEI) is an important metric for pumps exceeding 0.7. Using a pump with a high MEI can help users save money on energy costs, reduce their carbon footprint, and improve overall performance and reliability

We have specialised in corrosion resistant pumps since 1973 so can almost certainly find you a solution to your application. Our chemical resistance table shows just some of the liquids we have experience pumping, but please talk to us to find the best chemical pumping solution for you.

- Check the pump regularly for signs of wear and tear.

- Ensure the pump is properly lubricated.

- Check the bearings for any signs of wear or damage.

- Ensure that the pump is properly aligned with the drive motor.

- Check the temperature of the pump and ensure it does not exceed the recommended levels.

- Ensure that the pump is running at the correct speed.

Trusted By The Best