The advantages of using Plastic Pumps

Plastic Pumps Use in Industry – Thermoset plastics used in making pumps and pipelines and have been for well over 50 years.

Traditionally when faced with selecting pumps for handling corrosive liquids engineers were faced with using pumps made from high nickel content alloys such as Hastelloy or using pumps lined with ceramic or glass.

The advantages of using plastic pumps are many fold:

1) They are less expensive to manufacture, meaning cheaper prices for the customer.

2) Faster lead times!

3) Better corrosion resistance giving the pump a longer life.

4) Lighter in weight giving more manoeuvrability.

Plastics have come a long way in 50 years and are now readily available in bar from up to 500mm in diameter for polypropylene, PVC, PVDF and polyethylene. PTFE can be made in billet form and can be glass or carbon filled for better stability.

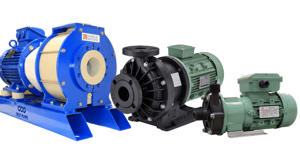

Crest Pumps has been manufacturing both horizontal and vertical pumps from engineered plastics since the early 1970’s and are very experienced in specifying and supplying centrifugal pumps for aggressive and corrosive applications in the chemical, effluent and water treatment, plating and anodising and associated industries.

EXPLORE OUR RANGE OF PLASTIC PUMPS

Typical applications would include:

- Chemical transfer

- Tanker offloading

- Sump emptying and control

- Fume scrubber re-circulation

- Plating tank re-circulation

The list is almost endless but for any application involving pumping corrosive liquids please contact us for a quotation. Call us 01425 627700 or get in touch here.

We often post articles and other news on our LinkedIn page so please go and follow to keep up to date or for any pump queries you may have please contact us.