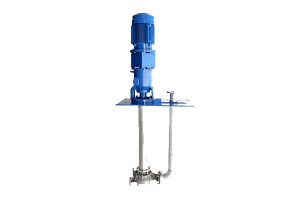

VERTICAL IMMERSIBLE PUMPS

Designed specifically for aggressive, corrosive environments, Crest Pumps’ vertical immersible pumps combine unmatched reliability with minimal maintenance needs—ensuring long-lasting performance even in the harshest conditions.

An immersible pump is different to a submersible pump because of the corrosive nature of the liquid, the motor is mounted above the tank with an extended shaft to the pump end at the bottom of the sump. The pump can be mounted internally or externally & shorter lengths are built without immersed bearings or seals meaning they have virtually no maintenance requirements or risk of failure.

Whether you’re emptying tanks, transferring chemicals, or recirculating aggressive fluids, our vertical sump pumps are engineered to fit your exact needs. They’re available in column lengths ranging from 300mm up to 6 meters, with options that require virtually no maintenance—thanks to designs without immersed bearings or seals.

Our surge, CSS, and cantilever pump ranges feature cantilever, seal-less designs that allow run-dry capability—meaning they can operate safely without fluid for indefinite periods. Made from corrosion-resistant materials, these pumps handle everything from clean liquids to solids-laden acidic or alkaline fluids.

Every sump is unique in size and contents, so we build each vertical pump to your precise specifications. Whether you need specific performance parameters, solids handling capability, or customized sizing, our expert team is ready to help design the perfect solution.

Featuring a standard 400mm column length. The vertical Surge range is suitable for all types of applications including metal treatment, tank emptying transfer and re-circulation

View Surge

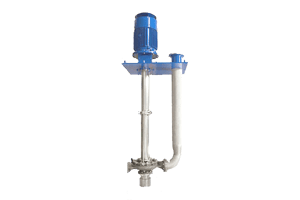

Built with a cantilever shaft design, CSS Pumps have no immersed bearings which allows the pump to run drywithout damage. Available in polypropylene or PVDF

View CSS

The PPS range of vertical immersible pumps is specifically designed for reliable and efficient chemical transfer. Built from durable thermoplastics with column lengths from 1m - 4.5m.

View PPS

Column lengths from 300mm on a cantilever shaft without bearings or bushings. Designed with a 'run dry' capability, they continue to perform even without fluid, and the 'fit and forget' philosophy ensures minimal maintenance, offering long-lasting, hassle-free operation.

View CANTILEVER

Extremely efficient when pumping harsh and corrosive chemicals that include solids 60% of the size of the discharge port. An ideal solution when emptying wastewater sumps.

View VERTICAL

What You Get When You Choose Crest Pumps

Trusted By The Best