Saving energy protecting the environment

At Crest, we are acutely aware of the pressing need to protect the environment at every level. This means getting your pumping solutions right. With Crest you can rest easy knowing that we specialise in environmentally-friendly solutions that take the guesswork out of locking in the best that state of the art technology can provide.

When you consider that pumps account for 10% of the world’s total energy consumption, you can see that our approach in supplying highly efficient pumps that minimise this consumption is vital in helping your system and the environment at the same time.

It is thought that two out of every three pumps and pump systems currently installed are wasteful of energy resources and that up to 60% of this energy could be saved by employing pumps with high efficiency motors and variable frequency drives.

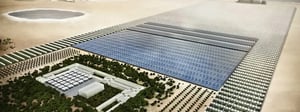

These technologies have been used by Crest Pumps on a worldwide level, for example in supplying pumps for desalination work to the Sahara Forest project, which aims to reverse the desertification of the Sahara, back to the days when this region of North Africa supplied two-thirds of the grain supply to the Roman Empire, no less!

Energy efficient pumps and pumping systems are big players in the environmentally significant fields of biofuel and biogas development, as well as the increasingly urgent area of energy storage. Crest is currently working with Vanadis Power in Germany. This company is in the forefront of developing a fuel cell that stores kinetic energy from solar power, creating a renewable energy source. It needed corrosion resistant pumps to be installed into the energy storage process. Crest recommended and supplied the magnetic drive AVF-X pumps for the process and duty required and for the ultimate corrosion resistance against this specialist application.

The costs of pump optimisation equates to 5% of lifecycle costs and 10% of maintenance costs. This represents a relatively low cost investment and can payback in one to five years, bringing cost and energy savings for the foreseeable future.

To find out how your pump system stacks up, talk to our experts about the environmentally-friendly solutions on offer here at Crest, by calling us on 01425 627700. We look forward to speaking to you.