Industrial Process Pumps for All Industries

We specialise in the manufacture and supply of corrosion resistant pumps for all process industries. As a UK manufacturer, we can tailor any pump to meet your specifications. Explore our diverse selection of pumps to find the perfect solution for your specific application.

Unplanned downtime damages both profits and reputations—but with Crest Pumps, you never have to worry. As a British manufacturer, we understand the need for process systems to run seamlessly, ensuring reliability when it matters most. Experience greater performance, reduced power consumption, and the same trusted reliability with Crest Pumps.

When we put our name on a pump, we make a serious commitment—offering lifetime support and pumps built to withstand even the most corrosive environments. With 50 years of expertise in chemical-resistant pump manufacturing, we’re here to help you find the right solution, whatever the challenge.

Ideal for processing clean corrosive liquids, The centrifugal force is driven by two rotating magnets eliminating the need for a mechanical seal, making the magnetic drive close coupled pump seal-less and leak proof.

View Range.png?width=300&name=Untitled%20design%20(1).png)

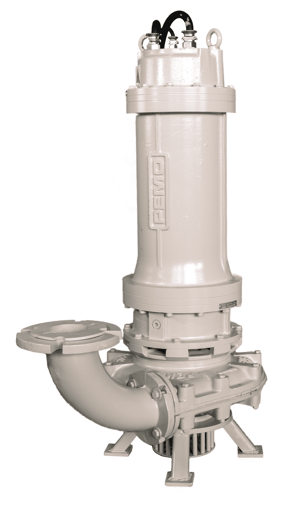

Mechanically sealed centrifugal pumps might be your best choice for larger flowrates or applications with solids. Ideal for various clean and dirty liquid transfer, water treatment, paper & pulp, and chemical process applications.

View Range

Resistant to clean or solids laden corrosive, acidic or alkali liquids making them suitable for all types of applications including sump emptying, recirculation and transfer. Available with column lengths from 400mm to 6m.

View Range

Air operated diaphragm pumps are positive displacement pumps that use compressed air instead of an electric motor. Ideal for self-priming, solids handling or run dry applications.

View Range

Find many other options from large abrasive handling slurry pumps to simple drum transfer pumps

View Range

Various accessories to help maximise pump uptime - from inverters and sealing systems, to strainers and priming chambers

View Range

What You Get When You Choose Crest Pumps

Trusted By The Best