HORIZONTAL END SUCTION MECHANICALLY SEALED PLASTIC & METALLIC PUMPS

British built thermoplastic mechanically sealed Crest Pumps, complemented with Salvatore Robuschi metallic pumps Stainless Steel, other exotic alloys or cast iron

Mechanically sealed centrifugal pumps are your best choice for larger flowrates or typical applications with solids. Ideal for various clean and dirty liquid transfer, water treatment, paper & pulp, & chemical process & acid pump applications.

As a British manufacturer of chemical resistant pumps, we understand how the financial and reputational cost of a plant shutdown is just unthinkable. As engineers, we all love our systems and processes to run like clockwork. That’s why reliability and longevity is at our core. For all the pumps supplied since 1973, we can proudly say that our reliability ratio is 99.98% meaning that you never have to worry about unplanned downtime again.

We’re also excited to strengthen our partnership with Salvatore Robuschi. After 12 years of successfully supplying their pumps under the Crest name, we are now the exclusive UK distributor for their industrial pump range. Moving forward, these high-performance pumps will be available under the SR Pumps brand, ensuring our customers continue to receive the same trusted quality and expertise.

.png?width=300&name=EOV-Product%20(1).png)

The EOV gives you up to 15% increase in performance while consuming up to 20% less power compared to the previous industry trusted ECC range. Featuring an improved vane design that increases efficiency by up to 35%

View EOV

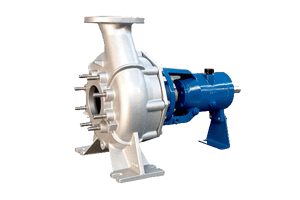

The RD-RG-RC-RB range of heavy duty end suction process pumps are designed for all applications from water to corrosive or solvents including ATEX Zone 1 and 2. Built to ISO2858 and En25199 and come with a choice of impeller designs to best fit your application

View RD-RG-RC-RB

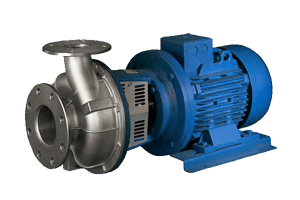

The HD-HG-RS ranges are suitable for a wide variety of applications including chemical transfer, pharmaceutical and food production. The modular design of this range makes the pump completely flexible to your business requirements

View HD-HG-RS

The ideal choice for corrosive applications, especially when solids are involved. Machined from solid thermoplastic, it gives outstanding strength and robustness for applications that demand longevity in the harshest of environments.

View PP

Designed to deal with the most corrosive low flow and high head applications. Ideal for reliable process pumping with applications up to 60m head and compatible with liquids ranging from caustic to hydrofluoric acid.

View PPM

Single stage centrifugal pumps suitable for clean liquids but can handle non abrasive solids <0.2% concentration. Can be ATEX certified for hazardous environments.

Read More

What You Get When You Choose Crest Pumps

Trusted By The Best