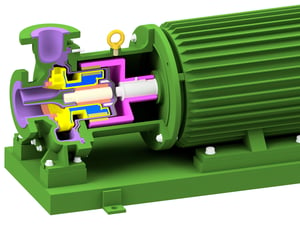

The AME range are heavy-duty process pumps designed with a metallic armour and high purity PFA-lining to handle the toughest applications and for transferring high purity aggressive chemicals. Designed to ISO 2858 standards, these magnetic drive pumps are built for reliable and leak-free operation in the most arduous of applications with temperatures <150°C thanks to the patented structural design.

Stop replacing pumps and start investing in performance.

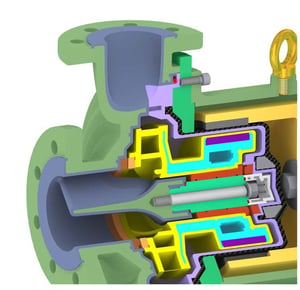

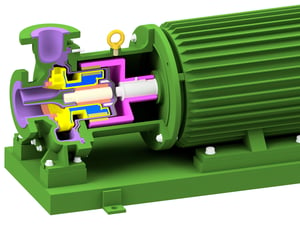

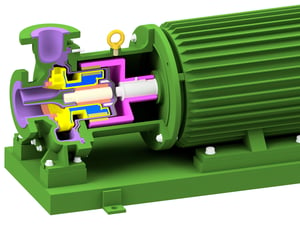

The biggest concern with heavy duty seal-less pumps made from engineering plastic has been the shaft support system as it must be strong enough to withstand the radial forces during operation. The AME range is designed to balance radial force and reduce the bearing load which also reduces the noise level as a result. The AME mag drive range feature a patented, integrated ‘V’ shape front support that is integral to the metal casing which is then PFA lined. This improves the liquid flow to the impeller, increasing operational efficiency, reducing NPSHr and ensuring a long service life. The one piece PFA lining and internal SSiC parts give outstanding chemical resistance to practically all corrosive applications, even at temperatures up to 150°C.

Benefits of the AME Range

A. Featuring a patented integral V shape front support that is part of the metal casing armour and then PFA lined. The rear of the shaft is supported in the PFA lined containment shell and reinforced by a metal support ring and high-strength carbon fibre composite cover. This superior design means a longer life resulting in far lass downtime and increased productivity.

B. The PFA lining is formed directly onto the metal armour and designed to ensure the PFA material remains adhered to the armour even under low absolute pressure.

C. The casing volute is designed to have an evenly distributed hydraulic pressure, providing a balanced radial loading on the impeller.

D/E. The impeller and magnet capsule are formed as one piece which eliminates the possibility of the impeller loosening. For further operational stability and rigidity, a metallic structure is embedded from the magnet capsule to the impeller blade further increasing the pump's operational life.

F. The stationary shaft design allows for a very simple construction which makes maintenance and repairs very simple.

G. The plastic containment shell is reinforced with a carbon fibre composite cover. There is no eddy current loss, so no additional heating of the pumped chemical.

H. Inner magnets are constructed from Samarium Cobalt (SmCo) in order to withstand high operating temperatures without experiencing demagnetization. High strength neodymium (NdFeB) is then used for the drive magnet to provide high torque transmission.

I. Simple and quick maintenance access without the need to remove the pump casing from the piping.

J. Designed to ISO2858, ISO5199, ISO15783, and EN809 standards.

THE CREST PUMPS LIFETIME GUARANTEE

No matter how old your pump becomes, in the unlikely scenario that you have a problem, our engineers will be on hand to diagnose the issue and help you get up and running again.That’s why, with Crest Pumps you’ll never need to worry about unplanned downtime again.

Talk to us now to discuss your chemical pump requirements or book a free site audit to see how much time and money you could save!

Built to outlast and outperform

Discover the significant savings you can achieve and explore the potential financial benefits that await you.

.jpg?width=300&name=AME%20(6).jpg)

.jpg?width=300&name=AME%20(3).jpg)

.jpg?width=300&name=AME%20(6).jpg)

.jpg?width=300&name=AME%20(3).jpg)

.jpg?width=300&name=AME%20(6).jpg)

.jpg?width=300&name=AME%20(3).jpg)

.jpg?width=300&name=AME%20(6).jpg)

.jpg?width=300&name=AME%20(3).jpg)

.jpg?width=300&name=AME%20(6).jpg)

.jpg?width=300&name=AME%20(3).jpg)

Technical Specification

| Model | INLET X OUTLET BORE SIZE (mm) |

IMPELLER DIAMETER (mm) |

RATED CAPACITY (m /hr) |

RATED HEAD (m) |

SHAFT POWER (kW) |

MOTOR OUTPUT (kW) |

| AME-BP | 40 x 25 | 160 | 10.8 | 34.4 | 1.8 | 1.5, 2.2 or 4 |

| AME-BT | 40 x 25 | 200 | 10.8 | 61.1 | 4.3 | 5.5 or 7.5 |

| AME-CP | 50 x 32 | 160 | 20 | 35.6 | 3.3 | 1.5, 2.2 or 4 |

| AME-CT | 50 x 32 | 200 | 24 | 49.5 | 6 | 5.5 or 7.5 |

| AME-EP | 65 x 50 | 160 | 30 | 32 | 4.8 | 5.5 or 7.5 |

| AME-FP | 80 x 65 | 160 | 50 | 32 | 6.5 | 5.5, 7.5 or 11 |

| AME-HT | 100 x 80 | 200 | 150 | 43.3 | 24.1 | 11,15,18.5,22 or 30 |

Frequently Asked Questions

Magnetic drive pumps are used in a wide variety of applications, including chemical processing, water treatment, and metal finishing. They are designed to provide a reliable and efficient solution for transferring corrosive and hazardous liquids. The pumps are constructed with a non-metallic construction, making them ideal for use in highly corrosive and hazardous environments.

Magnetic drive pumps are centrifugal pumps that use a magnetic coupling to transmit power from the motor to the impeller. The drive magnet is mounted on the motor shaft that will connect by magnetic force to driven magnets contained within the pump. This type of pump is ideal for applications where leakage or contamination of the pumped fluid is a concern, as there is no mechanical seal or shaft seal to fail.

We have specialised in corrosion resistant pumps since 1973 so can almost certainly find you a solution to your application. Our chemical resistance table shows just some of the liquids we have experience pumping, but please talk to us to find the best chemical pumping solution for you.

- Check the pump regularly for signs of wear and tear.

- Ensure the pump is properly lubricated.

- Check the bearings for any signs of wear or damage.

- Ensure that the pump is properly aligned with the drive motor.

- Check the temperature of the pump and ensure it does not exceed the recommended levels.

- Ensure that the pump is running at the correct speed.

Trusted By The Best

DON’T JUST TAKE OUR WORD FOR IT

Quick response times, knowledgeable engineers, and very co-operative in ensuring the correct pump was acquired for the right application.