A complete guide to gear pumps

A complete guide to gear pumps

Contents

What is a gear pump & how does it work?

Advantages & Limitations of Gear Pumps

Crest Pumps stock Pompe Cucchi gear pumps

Gear pumps are one of the most widely used types of positive displacement pumps - meaning they deliver a fixed volume of fluid for each rotation of their internal gears. They are rugged, reliable and work across a huge range of industries from manufacturing and chemicals to food processing and lubrication systems.

What Is a gear pump & how does it work?

A gear pump uses the rotation of gears to move fluid:

- Two meshing gears create expanding cavities on the intake side that draw fluid in.

- Fluid is then carried around the outside of the gears.

- As the teeth mesh again on the discharge side, the trapped fluid is forced out toward the outlet.

There’s no direct contact between inlet and outlet through the gears, so fluid never flows backward — making these pumps efficient for dosing and transfer. This process produces a smooth, steady (mostly pulse-free) flow — ideal for consistent metering and transfer applications.

Internal Vs External

While both internal and external gear pumps operate on the same positive displacement principle, their internal design, performance characteristics, and ideal applications differ in important ways. Understanding these differences helps ensure you select the right pump for your fluid and process.

External Gear Pumps

External gear pumps use two identical external gears mounted on parallel shafts. As the gears rotate fluid is drawn into the pump as the gears separate at the inlet. The liquid is then trapped between the gear teeth and the pump casing, and then the meshing gears force the fluid out at the discharge side.

External gear pumps use two identical external gears mounted on parallel shafts. As the gears rotate fluid is drawn into the pump as the gears separate at the inlet. The liquid is then trapped between the gear teeth and the pump casing, and then the meshing gears force the fluid out at the discharge side.

There is no fluid transfer through the centre of the gears — all movement happens around the outside.

Key characteristics

- Simple, robust design makes them highly reliable and easy to maintain

- They can operate at higher pressures than many internal gear designs, ideal for hydraulic systems, lubrications circuits and fuel transfer.

- Compact & cost-effective

- External gear pumps perform best with clean, lubricating liquids such as oils, fuels and coolants.

Internal Gear Pumps

Internal gear pumps consist of an inner (drive) gear, a larger outer gear with internal teeth and a crescent-shaped spacer between them. As the gears rotate fluid enters the pump as the gears un-mesh, liquid is then carried between the inner and outer gears, the crescent forms a seal separating suction & discharge areas. This then pushes the fluid out smoothly as the gears re-mesh.

Internal gear pumps consist of an inner (drive) gear, a larger outer gear with internal teeth and a crescent-shaped spacer between them. As the gears rotate fluid enters the pump as the gears un-mesh, liquid is then carried between the inner and outer gears, the crescent forms a seal separating suction & discharge areas. This then pushes the fluid out smoothly as the gears re-mesh.

Key characteristics

- Excellent for high-viscosity fluids. The larger cavities and smoother fluid path reduce resistance and improve suction.

- Smoother, quieter operation thanks to the gradual gear engagement and larger fluid pockets.

- Because of their design, internal gear pumps are more forgiving when pumping fluids whose viscosity changes with temperature.

Advantages and Limitations of Gear Pumps

Like any pump technology, gear pumps excel in certain applications and are less suitable in others. Understanding both sides helps ensure the pump you select delivers reliable performance and long service life.

Advantages

Consistent, predictable flow

One of the biggest advantages of gear pumps is their ability to deliver a smooth and repeatable flow rate. Because they move a fixed volume of liquid with every rotation, they are ideal for applications that require accurate dosing, metering, or controlled transfer — even when system pressure changes.

Excellent for viscous fluids

Gear pumps perform particularly well with medium to high-viscosity liquids, such as oils, resins, fuels, polymers, and syrups. Unlike centrifugal pumps, their performance does not drop off as viscosity increases — in fact, higher viscosity often improves sealing efficiency within the pump.

Compact and space-efficient

Gear pumps offer high performance in a relatively small footprint, making them ideal for skid-mounted systems, OEM equipment, and installations where space is limited.

Simple, robust design

With fewer moving parts than many other pump types, gear pumps are mechanically straightforward. This simplicity translates to high reliability, long service life and lower maintenance requirements.

Self-priming capability

Most gear pumps are self-priming, allowing them to draw fluid into the pump without needing to be flooded. This is particularly useful when pumping from tanks or sumps below pump level.

Wide material and configuration options Gear pumps are available in a broad range of materials (cast iron, bronze, stainless steel) and configurations, including: heated jackets for temperature-sensitive fluids, magnetic drives for leak-free operation and mechanical seals or packed glands.

Gear pumps are available in a broad range of materials (cast iron, bronze, stainless steel) and configurations, including: heated jackets for temperature-sensitive fluids, magnetic drives for leak-free operation and mechanical seals or packed glands.

Limitations

Limited tolerance for solids and abrasives

Gear pumps are designed for clean liquids. Even small solid particles or abrasives can cause accelerated wear to gears and internal clearances, reducing efficiency and pump life. For fluids containing solids, alternative pump technologies are usually more suitable.

Sensitive to dry running

Gear pumps rely on the pumped liquid for lubrication and cooling. Running the pump dry — even briefly — can cause rapid wear or damage to internal components. Proper suction conditions and system safeguards are essential.

Pressure relief is essential

Because gear pumps are positive displacement pumps, they will continue to build pressure if flow is restricted. Without adequate pressure relief valves, this can lead to seal failure, mechanical damage, or safety risks.

Efficiency decreases with wear

Over time, internal clearances can increase due to normal wear. This leads to internal slip, reducing volumetric efficiency. While gear pumps remain operational, performance gradually declines — making routine inspection and maintenance important.

Not ideal for shear-sensitive fluids

The meshing action of the gears can subject fluids to mechanical shear. While this is acceptable for most industrial liquids, it may not be suitable for shear-sensitive products such as certain emulsions or biological fluids.

Gear pumps are an excellent choice when you need reliable flow, compact design, and strong performance with viscous fluids. However, they require careful consideration of fluid cleanliness, lubrication, and pressure control. When correctly applied and maintained, gear pumps are among the most dependable and long-lasting pump solutions available.

Crest pumps stock Pompe Cucchi gear pumps

At Crest Pumps, we offer a wide selection of Pompe Cucchi gear and metering pumps, built to handle everything from simple transfer of oils to precision dosing and aggressive chemical handling. These pumps are engineered for performance, durability, and flexibility, and can be tailored with options such as mechanical seals, magnetic drives, and heating jackets.

Here’s a breakdown of the key series and what they’re best suited for:

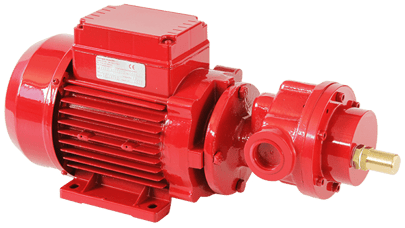

S, SK & SM Series – Heavy‑Duty External Gear Pumps

These are the workhorses of the gear pump range.

These are the workhorses of the gear pump range.

Flow: Up to around 60,000 L/hour, depending on size.

Pressure: Typically up to ~20 bar.

Best for: Oils, fuels, lubricating fluids, Resins, polymers, and non‑abrasive process liquids & Systems requiring steady pulseless flow.

Why choose them: Robust construction and adaptability make these pumps ideal for industrial transfer, lubrication systems, and continuous‑duty applications.

👉 Available in a range of configurations, including seal options and heated jackets for temperature control.

N Series – Efficient, Compact Transfer Pumps

The N Series is all about efficiency in a compact footprint:

Viscosity range: Suitable for low‑to‑medium viscosity fluids.

Performance: High volumetric efficiency with good suction capability.

👉 Great choice when you want efficient transfer without moving up to the largest pump sizes.

F Series – High‑Performance Transfer for Tough Jobs

The F Series is built for challenging transfer tasks:

The F Series is built for challenging transfer tasks:

Fluid types: Low‑to‑medium viscosity liquids without solid particles.

Temperature: Standard up to ~90 °C, options up to ~230 °C with suitable materials.

Pressure: Up to ~15 bar.

👉 Ideal for applications like fuel injection, additive dosing, and industrial oil handling where reliable suction and temperature management are important.

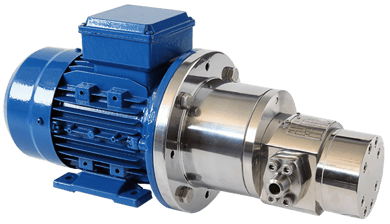

MX Series – Leak‑Free Magnetic Drive Gear Pumps

If you’re handling hazardous, corrosive, or difficult‑to‑seal fluids, the MX Series is a standout option:

Viscosity range: Effective for fluids from thin liquids up to ~100,000 cP.

Performance: Self‑priming design and excellent mechanical integrity.

👉 Especially suited for chemical plants, corrosive mediums, or systems where safety and environmental containment are priorities.

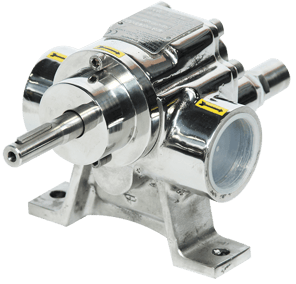

WP Series – Precision Metering & Dosing Gear Pumps

The WP Series is the gear pump you choose when accuracy matters:

Purpose: Engineered for metering, dosing, and process precision.

Purpose: Engineered for metering, dosing, and process precision.Flow: Up to ~480 L/hour.

Pressure: Up to ~15 bar.

Features: Modular design for easy integration, self‑priming for flexible installation.

👉 Widely used in chemical processing, pharmaceuticals, food, and cosmetics, where controlling flow rate matters just as much as the pump itself.

Gear pumps are robust, reliable, and highly versatile, providing smooth, precise flow for a wide range of fluids and applications. By choosing the right type and ensuring proper operation and maintenance, you can enjoy efficient, long-lasting performance and keep your processes running smoothly.

Ready to find the perfect gear pump for your needs? Explore our full range of pumps or speak to one of our experts today to get tailored advice and support for your application.