A complete guide to liquid ring vacuum pumps

A complete guide to liquid ring vacuum pumps

Contents

What is a liquid ring vacuum pump?

How does a liquid ring vacuum pump work?

Can liquid ring pumps handle dirty or wet gases?

Helpful tips for selecting & operating a liquid ring vacuum pump

SR liquid ring vacuum pumps from Crest Pumps

Liquid ring vacuum pumps are a proven and reliable vacuum solution used across a wide range of industries. Known for their ability to handle wet gases, vapours, and even small amounts of liquid carryover, they are often chosen where other pump technologies struggle.

This guide explains how liquid ring vacuum pumps work, where they are best used, their advantages and limitations, and what to consider when selecting one. We’ve also included commonly asked questions and an overview of the SR (Salvatore Robuschi) liquid ring vacuum pumps available from Crest Pumps.

What Is a Liquid Ring Vacuum Pump?

A liquid ring vacuum pump creates vacuum using a rotating liquid rather than close mechanical tolerances or oil-sealed vanes.

Inside the pump casing, a liquid — most commonly water — forms a rotating “ring” that seals, compresses, and expels gas. This simple but effective principle makes liquid ring pumps especially well-suited to wet, dirty, or vapour-laden applications.

Because the gas never comes into contact with oil or tight internal clearances, liquid ring pumps are extremely tolerant of challenging process conditions.

How Does a Liquid Ring Vacuum Pump Work?

The working principle is straightforward:

- The pump casing is partially filled with a sealing liquid.

- A rotor mounted off-centre rotates inside the casing.

- Centrifugal force pushes the liquid outward, forming a rotating liquid ring against the casing wall.

- The off-centre rotor creates varying chamber volumes between the rotor blades and the liquid ring.

- As these chambers expand, gas is drawn in through the inlet.

- As they contract, the gas is compressed and discharged through the outlet.

The liquid ring acts as a seal, compressor, and coolant all at once, which is why these pumps are so robust and forgiving in operation.

Typical Applications for Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps are commonly used where moisture, vapours, or fluctuating loads are present. Typical applications include:

Chemical processing – distillation, evaporation, solvent recovery

Pharmaceutical and food industries – drying, deaeration, filtration

Pulp and paper – vacuum dewatering and forming processes

Power generation – condenser evacuation and air removal

Wastewater treatment – vapour extraction and gas handling

General industrial vacuum – where reliability is more important than deep vacuum levels

They are often chosen specifically because other pump types would suffer damage or reduced life in the same conditions.

Key Advantages of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps offer several important benefits:

Excellent Handling of Wet and Condensable Gases

These pumps are ideal for applications involving steam, vapours, or saturated gases. Condensation inside the pump is not a problem — it’s part of normal operation.

Oil-Free Vacuum

Because the pump uses a liquid seal rather than oil, there is no risk of oil contamination in the process gas.

Simple, Robust Design

With relatively few moving parts and no metal-to-metal contact inside the pumping chamber, liquid ring pumps are known for long service life and steady performance.

Quiet and Low Vibration

The liquid ring naturally dampens noise and vibration, making these pumps quieter than many alternative technologies.

Low Maintenance Requirements

Routine maintenance typically focuses on bearings, seals, and the condition of the sealing liquid, rather than frequent internal rebuilds.

Limitations to Be Aware Of

While liquid ring vacuum pumps are extremely versatile, they are not suitable for every application.

- Vacuum level is limited – single-stage liquid ring pumps typically achieve down to around 30–33 mbar absolute.

- Sealing liquid management is required – water supply, cooling, and discharge must be considered.

- Efficiency can vary – especially if the sealing liquid temperature rises or vapour pressure increases.

Understanding these limitations early helps ensure the correct pump is selected for the application.

Can liquid ring pumps handle dirty or wet gases?

Yes — this is one of their main advantages. They tolerate moisture, vapours, and small amounts of liquid carryover far better than many other pump types.

Helpful Tips for Selecting and Operating a Liquid Ring Vacuum Pump

- Consider sealing liquid temperature — warmer liquid reduces achievable vacuum.

- Choose materials carefully — corrosive gases may require stainless steel or specialised materials.

- Plan liquid recovery or recirculation — closed-loop systems can reduce water consumption.

- Avoid oversizing — matching the pump to the actual duty improves efficiency and reliability.

- Think about installation space — mounting options can affect access and maintenance.

Good pump selection is as much about understanding the process as it is about choosing a model.

SR (Salvatore Robuschi) Liquid Ring Vacuum Pumps from Crest Pumps

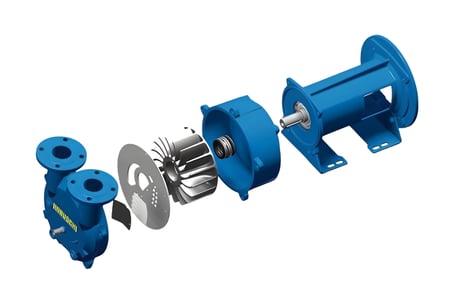

Crest Pumps supply the SR (Salvatore Robuschi) VS series liquid ring vacuum pumps; a well-established range designed for industrial vacuum applications.

Key Features of the SR VS Range

- Single-stage liquid ring vacuum pumps

- Vacuum capability down to approximately 33 mbar

- Flow rates from around 35 m³/h up to 1600 m³/h

- Multiple mounting configurations, including close-coupled, lantern bracket, and baseplate-mounted designs

- Robust construction, with corrosion-resistant materials and stainless-steel distribution plates as standard

- Designed for continuous, reliable operation

These pumps are suitable for a wide variety of industrial duties where reliability, simplicity, and tolerance of wet gases are essential.

These pumps are suitable for a wide variety of industrial duties where reliability, simplicity, and tolerance of wet gases are essential.

Beyond supplying the equipment, Crest Pumps provide technical support, pump selection advice, and aftersales assistance to ensure the right solution is chosen for each application. Talk to us today!